The OSM (Open Standard Module) specification, officially adopted by the SGET (Standardization Group for Embedded Technologies e.V.) in 2021, heralded the world’s first manufacturer-independent standard for solderable Computer-on-Modules. This is now being followed by a second wave of standardization as OEMs seek to switch from proprietary solutions to a unified standard across the entire range of ultra-low-power application processors.

Solderable Computer-on-Modules are not entirely new, with various manufacturers having offered proprietary Computer-on-Modules that can be SMT assembled for some time. Unlike classic Computer-on-Modules that require manual THT assembly, these solderable modules allow OEMs to benefit from fully automated assembly and test processes. However, standardization of such modules has been lacking until now.

Consequently, each module comes in a different form factor and features different pinouts. This leads to vendor lock-in and long-term availability depending on a single manufacturer. There are no independently maintained specifications, design guides, or a broad developer community, let alone open-source initiatives. Development houses specializing in carrier boards for solderable Computer-on-Modules are also missing, as is the entire ecosystem common in the traditional Computer-on-Modules scene. OEM customers must either integrate the modules themselves or rely on the module manufacturers to implement the design, which requires a great deal of trust and carries a higher design risk than with standardized Computer-on-Modules.

OSM targets ultra-low-power processors

With the availability of the OSM standard, things are now changing. And the shift is occurring at an opportune time, as more and more applications are being implemented with ultra-low-power processors up to 8 Watts, which can generally be designed without heat sinks. The Internet of Things (IoT) and the associated desire to make as many devices as possible ‘smart’, for example to manage them via smartphone apps, is drastically increasing the need for simpler integration of such application processors – even for industrial batch sizes, for which Computer-on-Modules are essentially designed.

In general, Computer-on-Modules offer an application-ready computing core with all specified interfaces in a fully validated package, including all standard drivers and the necessary OS support. This significantly shortens the time-to-market and reduces NRE costs immensely. Standardized Computer-on-Modules also provide typical advantages such as second-source availability, scalability across processor generations, manufacturers, and even architectures, thus ensuring long-term availability and safeguarding investments. This offers OEMs a high level of design security and maximum return on investment. By deploying Computer-on-Modules, costs can also be saved in relation to circuit boards, as a high current density often only exists directly at the processor. Once it is distributed on the carrier board, fewer layers can be used.

It’s not only the connector that costs money

However, when it comes to leveraging ultra-low-power processors, pluggable Computer-on-Modules are not the most efficient choice as they require several additional investments that partly negate the advantages of the cheaper processors. These investments include procurement of the actual connector, THT assembly, screw fixes and locknuts, as well as equipment to test the modules. In addition, test stations for pluggable COMs require regular replacement of the test board for larger series production runs, as the connectors are specified for a limited number of mating cycles – usually no more than a few hundred. Packaging is also more complex, involving antistatic pressure-sealed bags, bubble wrap or foam packaging, and cardboard boxes, with each module often individually packaged. RMA management is not only time-consuming; it also wears out the test stations. In this respect, the concept of pluggable Computer-on-Modules is only truly worthwhile for high-performance processors costing around 70 euros, where the additional expenses are less significant, accounting for 5-10% of the cost per module. For more expensive processors, the percentage is even lower.

OSM modules increase cost efficiency

Conversely, the cheaper ultra-low-power processors require significantly less costly solutions to bring them to market as application-ready modules at an affordable price. After all, the design-in is generally less complex, making full-custom designs more viable. A clearly more cost-effective solution is the use of solderable Computer-on-Modules, also known as System-on-Modules in the ARM segment. They can be assembled, tested, and packaged fully automatically. When standardized, the equipment to test the modules can also be standardized and used across all modules, banishing wear and tear. Stored in blister packs, shipped, and prepared for SMT assembly, the entire complex packaging management and associated costs are also eliminated. This makes modules a viable solution even for simple 32-bit processors that cost only a few euros/dollars.

Full-custom designs become less attractive

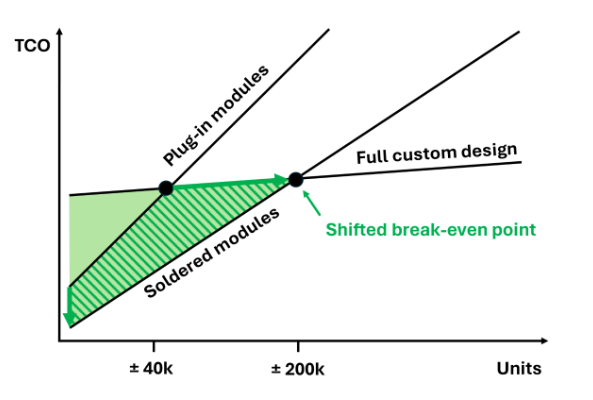

It is also worth noting that the design decision is significantly shifting from full-custom designs towards module and carrier board solutions. With THT-assembled modules, the amortization limit for the finished embedded system is typically around 20,000 units. However, the potential cost savings from SMT assembly are so significant that the break-even point is expected to increase to around 200,000 units. These are only rule-of-thumb values, which can vary depending on the setup. What is certain, however, is that solderable Computer-on-Modules can be used to address significantly larger-volume production runs, which expands the target market immensely and therefore also increases demand. The larger target group, in turn, enables faster market growth, leading to lower prices thanks to better economies of scale. All of this, coupled with availability in a standardized, non-proprietary format, promotes competition, which ultimately benefits OEMs and is why the proprietary market for solderable Computer-on-Modules is coming under increased pressure with the launch of the OSM standard.

Clear pin specifications

However, the OSM standard includes an often-misunderstood provision, namely that there are no mandatory pin assignments. Without a more detailed explanation, this might lead to the assumption that everyone can do as they please, raising the question: Where’s the difference between proprietary and standardized Computer-on-Modules? This lies in the optional specifications, which ultimately provide a rather stringent master plan for the assignment of pins. The OSM form factor ‘Large’ has up to 660 pins (even COM-HPC Server modules only have around 21% more pins!) and it is clearly defined which pin can execute what. However, it is not obligatory to assign pins – and this offers immense advantages.

100% interoperability

It means OSM modules are 100% interoperable and can be deployed on any OSM-compatible carrier. The optional specifications also make it possible to offer highly dedicated and therefore very heterogeneous SoCs on a single standard because 600 pins provide enough space for all common interfaces. One potential issue is that the optional interface specification states that five Ethernet interfaces are only possible for size L modules and upwards. So, there is a clearly defined range of functions for each module size, which could have been different for some processors. For example, highly specialized switch controllers that would also fit on size M modules. Ultimately, the only difference between standardized OSM modules and previous Computer-on-Modules is that there are fewer mandatory specifications, which some processor manufacturers had used to deny competitors access to the Computer-on-Module business by exerting influence on the specification of the pinouts. This prevented competitors from leveraging the multiplier effect of Computer-on-Modules. However, by replacing mandatory with optional interfaces, the standard becomes compatible for almost all ultra-low-power SoCs, which are available in highly heterogeneous designs.

Full flexibility

This makes the OSM standard exceptionally open and future-proof – even for very dedicated solutions with automotive interfaces or integrated FPGAs, for instance. New or not yet common interfaces can in the future simply be assigned to unused pins or replace obsolete ones. For functions that will never exist in combination, pins can be assigned multiple times. Such flexibility creates the necessary design security in the heterogeneous field of highly integrated ultra-low-power SoCs.

Leading manufacturer support

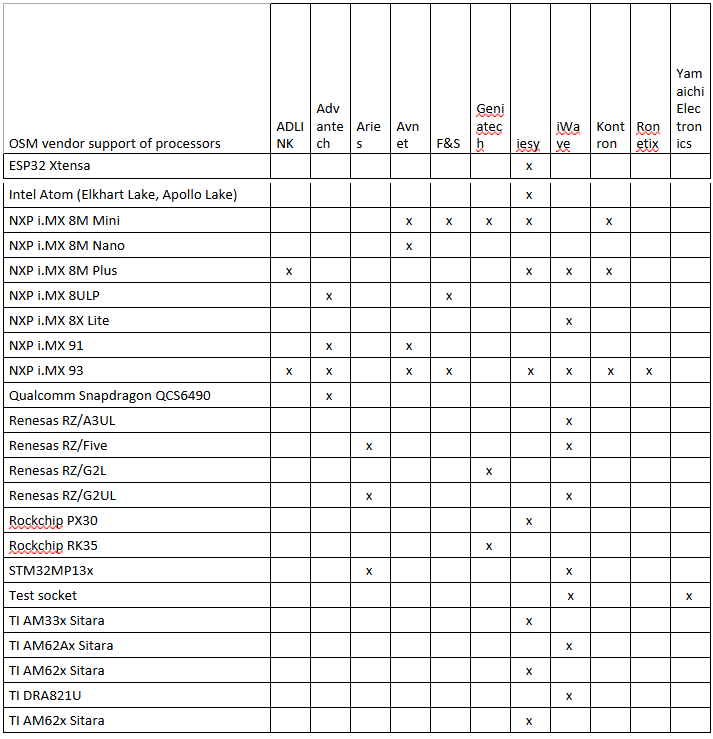

SGET members Advantech, Aries, Avnet, F&S, Geniatech, iesy, iWave, and Kontron are the first manufacturers to offer official OSM modules. The ecosystem surrounding the modules is also growing. The first carrier board developers are already advertising that they offer not only classic COMs but also designs with OSM modules. Manufacturers such as iWave and Yamaichi are also selling test adapters for OSM modules. Application-ready Gen2 Computer-on-Modules supporting the OSM standard are already available in numerous variants:

One carrier board for all OSM modules

All these modules can be tested on the same carrier board, provided they support the full range of OSM pin functions. This homogenizes the design-in and simplifies the re-use of PCB layouts. One test system can be used for all OSM modules, without the wear and tear effects associated with connectors. Costs decrease and flexibility increases when evaluating a wide variety of processors. It becomes possible to build highly heterogeneous product families using one basic layout, which can result in enormous economies of scale. Even tricky tasks such as the carrier board antenna design can be reused, as OSM has incorporated these signals into the pin specification as well, enabling connectorless antenna designs.

Today, most OSM modules still come with pre-tinned and non-tinned contact pins. However, the even more advantageous BGA variants are likely to appear more frequently in the future, once the second wave of standardization has expanded. From certain volumes upwards, investing in the simpler and reliable SMT process will ultimately be worthwhile to gain a competitive advantage and offer added value.

Note that SGET membership is required to manufacture OSM modules. Nevertheless, the specification is open-source and is provided under Creative Commons license, both in terms of hardware and software. This also increases trust in the OSM standard. It will be interesting to see whether there will also be OSM modules for Arduino or Raspberry Pi in the future. It’s certainly something that would be possible from a technical perspective.

Author: Ansgar Hein is Chair of the Standardization Group for Embedded Technologies e.V. (SGET)

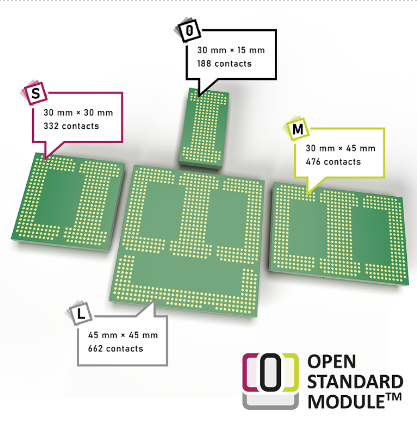

Open Standard Module (OSM): Visual representation of the four different sizes with Size-0, Size-S, Size-M and Size-L and the visible bottom-side of the modules.

Image showing the various module sizes

Caption 1: Solderable OSM Computer-on-Modules come in four sizes. As the standard pins of size S are also available on the other module sizes, the larger modules “just” have added functionality.

Caption 2: The OSM standard pushes the break-even point for full-custom designs towards 200,000 units.

Source: SGET

Caption 3: The currently available OSM modules are extremely heterogeneous, yet can all be tested on the same carrier.

芯耀

芯耀

1024

1024

下载ECAD模型

下载ECAD模型